| Brand Name: | HUAMEI |

| Model Number: | Silicone Release Film |

| MOQ: | 6200 square meter |

| Price: | 0.24-1.64/㎡ |

| Payment Terms: | L/C,D/P |

| Supply Ability: | 300000m everyday |

| Attribute | Value |

|---|---|

| Raw Material | PET |

| Color | Blue or customized |

| Width | Customized according to user needs |

| Length | Customized according to user needs |

| Thickness | 19 or customized |

| Release Force | 1-180 |

| Residual adhesion rate | ≥80 |

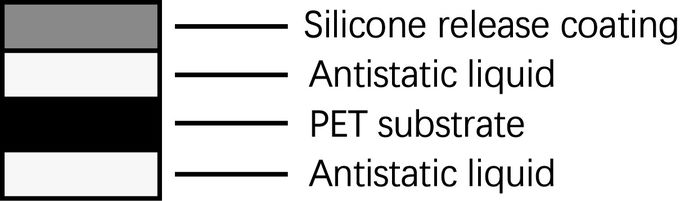

PET substrate using a high-performance, front coated with release coating, antistatic treatment on the back, making products with anti-static function, reduce negative phenomena caused by static electricity.

1. Electronics Industry

Component Protection: Anti-static PET film is used to protect sensitive electronic components from static discharge during manufacturing, storage, and transportation. Static electricity can damage electronic components, so the anti-static properties of the film are crucial.

Screen Protectors: It is used to make anti-static screen protectors for electronic devices such as smartphones, tablets, and computer monitors.

Insulation: The film is used as an insulating material in various electronic applications where static control is necessary.

2. Optical Applications

Optical Films: Anti-static PET film is used in the production of optical films for displays and touchscreens, where static discharge can cause visual defects.

Light Guides: It is used in light guide plates and other optical components where static control is necessary to maintain clarity and performance.

3. Photography and Imaging

Film and Photo Paper: Anti-static PET film is used in the production of photographic films and photo paper to prevent static discharge that could cause artifacts or damage to the images.

Inkjet Printing: It is used as a substrate for inkjet printing to ensure high-quality prints without static-related defects.

| Project | Eigenvalues |

|---|---|

| Membrance | Raw materials |

| Color | Customized according to user needs |

| Width(mm) | Customized according to user needs |

| Length(mm) | Customized according to user needs |

| Thickness( μm) | 19-150 |

| Surface resistivity( Ω*m) | 10^5-10^9,10^9-10^11 |

| Coating color | Light grey,transparent,light blue |

| Solvent resistant wiping | Customized according to user needs |

| Release Force(g/in) | 1-180 |

| Residual adhesion rate(%) | ≥ 80 |

| Conventional range from the type of power | 2 ±1,4±1,7±2,10±3,15±5,20±5,25±5,30±5,35±5,45±10,50±10,60±10,70±15,90±15,100±20,120±20,150±30 |